THE DECKER LOG LOADER

© pierreparis

The TRS2004 Models and the Kuid

table

How to install the scenery and the

industry versions in the surveyor

How to use the industry

interactive version

How to use of the loco version

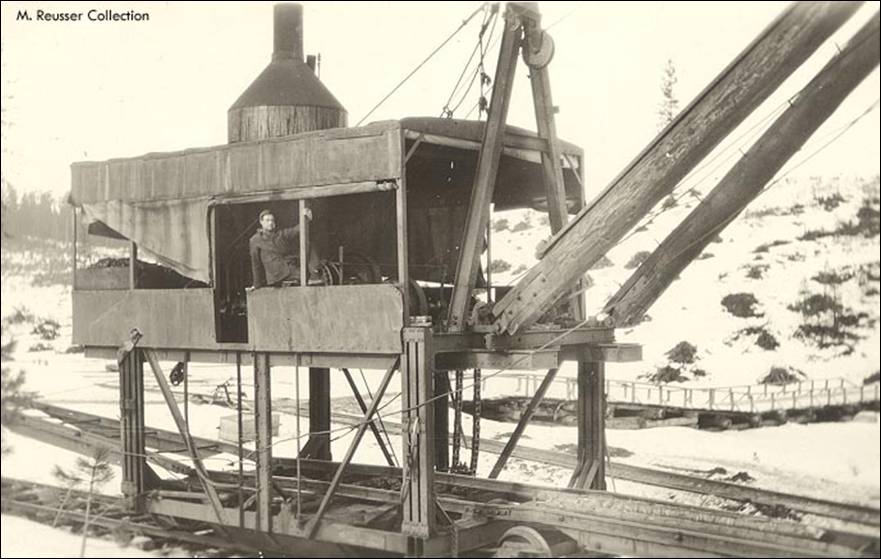

DESCRIPTION

(Source: www.steaminthewoods.com with the authorization of Marc Reusser)

(Excerpted from a Clyde Iron Works equipment catalog)

”The Decker machine is another type of self- propelling loader, of which we

are the exclusive manufacturers. Like the McGiffert

loader, it travels upon the same track over which the logging cars pass, and

permits the logging cars to run through it. In the Decker device, however, the

cars run over the loader trucks instead of under them, as in the McGiffert construction.

The body of the Decker loader is a sort of two story car. The lower deck is

open at each end, and is of such

width as to permit the passage of empty cars. The upper deck,

upon which are mounted the engine and hoisting mechanism, is supported upon

standards or posts, which rest upon the bolsters. A portable track is

secured to the lower deck; this track is provided with hinged end sections, which

may be lowered to the main track, and thus form a

continuous railway through the machine.

CONSTRUCTION

Body Frame - The frame of the Decker loader, which is subject to enormous

strains incident to the handling of heavy logs, is constructed entirely of

structural steel. The body bolsters which sustain the entire weight of the

superstructure, are composed of three ten-inch I beams,

plated above and below, to form a solid girder. From the ends of the body

bolsters, at each corner of the frame, standards extend upward. These are each

composed of three six-inch I beams. Cross girders composed of I beams and

plates are secured between each pair of standards at a sufficient height to

accommodate the empty cars.

The deck beams which support the engine and boiler and the floor of the

machine, are riveted to the underside of the cross girders, thus reducing the

height of the upper deck. The sides of the frame are built up of channels set

flush with the inside of the corner standards. This leaves sufficient space for

the sprocket chains and other connections on the side, without extending them

beyond the outside line of the standards.

A thorough system of bracing is used throughout and all parts are hot riveted

together.

The trucks are of the standard four-wheel type, and aside from the wheels, are

of steel. The truck bolsters are hung low to reduce the height of the machine.

M. C. B. journals, journal boxes, brasses and wedges are provided. Standard

24-inch double plate car wheels are used unless otherwise specified. When,

however, the machine is to be operated on a defective track, we prefer a wheel

with a five inch tread and 1 5-8 inch flange. For use on wood rail, we furnish

wheels with 6 inch tread and 2 1-2 inch flange.

The portable tracks are made of heavy, standard section rail thoroughly

trussed. The inclined sections are provided with forged steel points, which are

flexibly connected, so as to adjust themselves to the ball of the rail, and

afford a smooth surface for the car wheels. The approaches are elevated by

means of cables, operated by the engine. When the track is in fair condition,

it is not necessary to raise them in making short moves.

Steel water tanks of sufficient capacity for a day's run are secured under the

portable track, and between the trucks. The low position of

these tanks serve to steady the machine.

For propelling the machine, an extension shaft is connected with the engine by

means of a steel clutch. This shaft drives a second shaft, journaled

upon the lower deck beneath the portable track, the connecting chain running

down the side of the frame between the forward and rear standards. This latter

shaft is connected by sprockets and sprocket chains with the truck axles at

each end of the loader, thus making all of the wheels drivers. As the engine

has sufficient power to slip the wheels upon dry rails, the traction efficiency

is high, enabling the loader not only to handle heavy loads, but to climb

exceedingly heavy grades.

A friction brake wheel is mounted on the lower propeller shaft. . This brake is

operated by a lever located upon the upper deck of the machine within easy

reach of the engineer.

The boom of the Decker loader is of the rigid A-shaped type. This boom is

secured in heavy castings, bolted to the forward cross girder of the frame. It

is held at the proper elevation by means of guy cables, which extend back to

the rear corners of the frame. The boom band at the peak of the boom, the

loading and skidding blocks and other boom attachments, are similar to those

which are used on the McGiffert loader.

ENGINE AND BOILER

Power is furnished by a double horizontal cylinder, two-drum hoisting engine,

specially designed to withstand the strains incident to the handling of logs,

and the propelling of the machine itself. All gears are of cast steel and the

drums are bronze bushed. Each drum works independently, and is operated by

means of "V" friction. The drums are also provided with steel

ratchets. The engine bed is of one solid, casting made to also afford a base

for the boiler, so that all piping, shafts and gearing are firmly held in

proper place, thus maintaining tight steam joints and a perfect alignment of

the working parts. All levers are within easy reach of the engineer. From one

point he is thus enabled to readily and quickly control all the movements of

the machine.

The boiler is double riveted and is licensed to carry 125 pounds steam

pressure. A triple riveted boiler can be furnished where conditions are such as

to require higher pressure.

As the Decker loader rests always upon its trucks, it may be used for loading

at any point along the track where loaded cars may be handled. It is immaterial

whether the machine stands upon a trestle or a fill, as the required foundation

is always present. It needs no blocking or other special provision for its

support. The Decker is particularly adapted for operating on light steel or

wood rails, as its weight is well distributed. It is used very extensively

under these conditions and has given the highest satisfaction. The fact that

the Decker machine at no time rests upon the empty cars permits it to be used

without detriment in connection with cars of light construction. The Decker

machine is designed for either standard or narrow gauge track.

OPERATION

The train of empty cars is backed through the machine, preparatory to loading,

either by the road engine or by means of a spotting line. The spotting line is

then secured at the rear of as many cars as are to be loaded at one point, and

these cars are then drawn through by means of the spotting line and brought

successively into position under the boom to receive their loads. Where short

moves only are to be made, the machine may be moved without elevating the

inclined sections of the portable track, and even without removing the cars

that may be resting upon the portable track. Where the logs are scattered along

the track in such a position that they may be loaded upon cars without moving

the train, the cars may be held in a fixed position and the machine backed

under the train, moving from car to car as required.

For loading, either end hooks or tongs may be used. Where the logs are skidded

parallel with the track the end hooks are usually preferable. The Decker

machine may be provided with skidding line, and other necessary skidding

attachments. When so equipped it serves admirably as a combination machine.

[Typical operation consists of] The logs are skidded into the track by means of

the skidding line, the skidding tongs being secured to the end of the log. It

is drawn in until its forward end is over the car. The tongs are then shifted

to the center and the log swung into position. The same cable is ordinarily

used both for loading and skidding. The shifting of the tongs for the loading

requires but a moment. When there are no cars at hand the logs are piled up

along the track.

The facility with which the Decker may be used under the most difficult

conditions has made it a most popular machine for mountain logging. While a few

teams are usually found desirable for bunching the logs, in several operations

a single Decker is supplying the full requirements of the mill without other

logging means of any sort.”

THE TRS2004

MODELS AND THE KUID TABLE

Three models were made for TRS2004: a scenery,

an industry interactive and a loco. Each model exists in two versions: one for

the standard gauge and one for the 3 ft narrow gauge. There is a pack for each

version. Some assets are common to several versions. You will need also some

external assets from Slugsmasher

(Rich Blake), Elvenor and narrowgauge

(P.Pardoe-Matthews). Thanks to us for their

contributions.

The industry version is compatible with the Multi Log

(M-Log) system that Rich Blake is developing. It controls all the AI trains

trying to pass through the loader (see below ‘How to use the industry

interactive model). Keep in mind that the scenery model doesn’t

carry out this control. So the AI train can pass through

the scenery loader in a non realistic way.

There is no spotting line operation. The log cars must

be shoved back by a locomotive until the loader, and then pulled down to be

loaded.

You will found the scenery and the industry models

under USA/logging and the loco models under US/logging.

KUID TABLES

Scenery and Industry model:

|

Kind |

Name |

KUID2 |

Pack

Decker log loader SG as scenery |

Pack

Decker log loader NG3 as scenery |

Pack

Decker log loader SG industry |

Pack

Decker log loader NG3 industry |

|

Mocrossing |

Decker_log_loader_NG3_scenery |

86528:38004:0 |

|

X |

|

|

|

Mocrossing |

Decker_log_loader_SG_scenery |

86528:38006:0 |

X |

|

|

|

|

Industry |

Decker_NG3_industry |

86528:38010:0 |

|

|

|

X |

|

Industry |

Decker_SG_industry |

86528:38012:0 |

|

|

X |

|

|

Mesh |

Dll_scenery_bogey_NG

3 |

86528:38100:0 |

|

X |

|

X |

|

Mesh |

Dll_scenery_bogey_SG |

86528:38102:0 |

X |

|

X |

|

|

Mesh |

Dll_scenery_incline_track_NG

3 |

86528:38103:0 |

|

X |

|

X |

|

Mesh |

Dll_scenery_incline_track_SG |

86528:38105:0 |

X |

|

X |

|

|

Mesh |

Dll_scenery_transmission |

86528:38106:0 |

X |

X |

X |

X |

|

Mesh |

Dll_scenery_loading_line |

86528:38107:0 |

X |

X |

X |

X |

|

Mesh |

Dll_scenery_steam_engine |

86528:38109:0 |

X |

X |

X |

X |

|

Mesh |

Dll_scenery_character |

86528:38110:0 |

X |

X |

|

|

|

Mesh |

Dll_scenery_character2 |

86528:38111:0 |

|

|

X |

X |

Dependencies:

|

Model |

Kind |

Name |

KUID/KUID2 |

Author |

|

Industry |

Product |

32ft_logset |

86661:9440302 |

Slugsmasher |

|

Industry |

Product |

40ft_logset |

86661:9440303 |

Slugsmasher |

|

Industry |

Product |

16ft_logset |

86661:9440304 |

Slugsmasher |

|

Scenery and

industry |

Track |

MAN6 Invisible Track |

63290:38102 |

Elvenor |

|

Industry |

Texture |

Mlog_icon |

86661:9000100:1 |

Slugsmasher |

Loco model:

|

Kind |

Name |

KUID2 |

Pack

Decker log loader SG as loco |

Pack

Decker log loader NG3 as loco |

|

Traincar |

Decker_log_loader_NG3_loco |

86528:38007:0 |

|

X |

|

Traincar |

Decker_log_loader_SG_loco |

86528:38009:0 |

X |

|

|

Bogey |

Dll_loco_bogey_NG3 |

86528:38200:0 |

|

X |

|

Bogey |

Dll_loco_bogey_SG |

86528:38202:0 |

X |

|

|

Bogey |

Dll_trans_bogey |

86528:38203:0 |

X |

X |

|

Bogey |

Dll_steam_engine_bogey |

86528:38204:0 |

X |

X |

|

Pants |

Dll_loco_track_NG

3 |

86528:38300:0 |

|

X |

|

Pants |

Dll_loco_track_SG |

86528:38302:0 |

X |

|

|

Traincar |

Dll_reach_bar |

86528:38400:0 |

X |

X |

|

Traincar |

Dll_reach_bar_automatic |

86528:38401:0 |

X |

X |

Dependencies:

|

Kind |

Name |

KUID/KUID2 |

Author |

|

Engine |

Climax Engine File |

44700:51003 |

narrowgauge |

|

Enginesound |

Climax Steam Sounds |

44700:53003 |

narrowgauge |

|

Hornsound |

Climax Whistle |

44700:54003 |

narrowgauge |

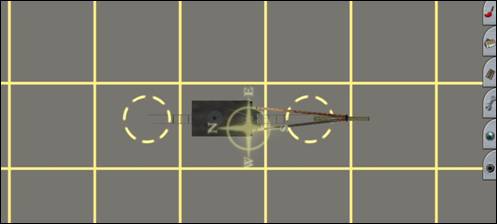

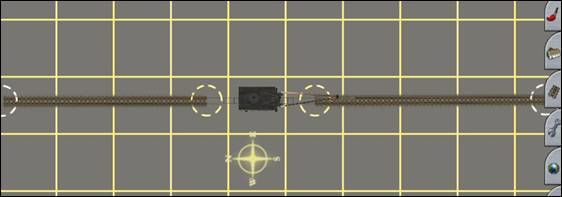

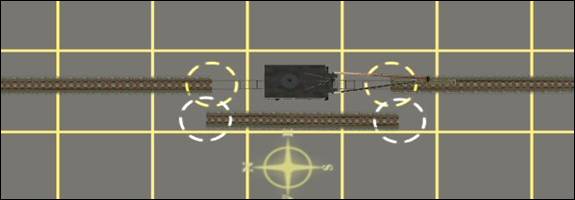

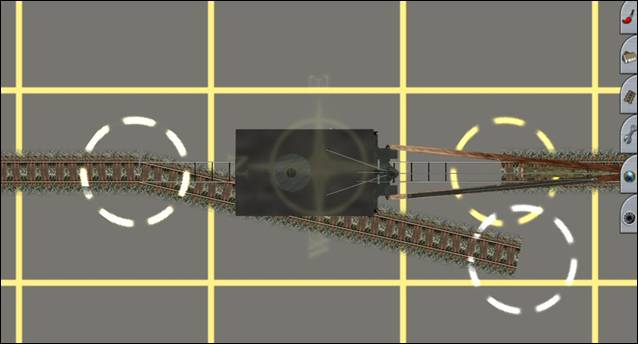

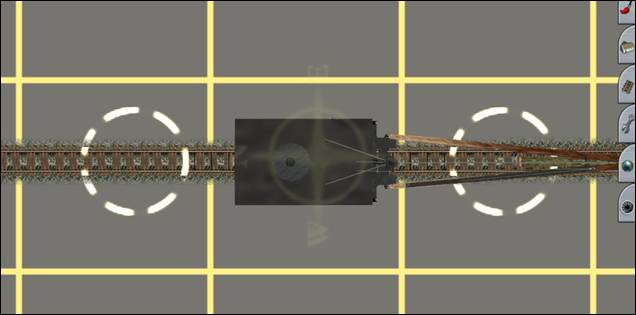

HOW TO INSTALL

THE SCENERY AND THE INDUSTRY VERSIONS IN THE SURVEYOR

Place the Decker log loader

Connect a piece of track at

each spline point of the Decker Log Loader

Place a new track near the log

loader

Move this track without

connect it (shift key down while moving it) under the log loader

The cars will use the upper

track (the track that pass through the loader) and not the lower track

HOW TO USE THE

INDUSTRY INTERACTIVE VERSION

This version controls the AI trains whatever there destinations and

there schedules.

When the AI train comes to the back of the Decker, it is stopped and a

message is displayed in the radio message box. The user must cancel the current

driver command. The same when the train comes to the front of the Decker with

the loco first.

When the train comes to the front of the loader with the cars first (the

loco shoves the empties cars towards the front of the loader), the industry

script drives the train thought the loader until the loco is just in front of

it, then reverse the direction of the train and proceed to the loading of each

car.

The user must insert a turnaround procedure, if required, in the

schedule of the driver, to make so that the loco shoves the empties toward the

front of the loader.

The manual driven trains are managed as usual, without any control. Each

car is loaded if stopped under the boom of the Decker.

The products used (M-Log compatible)

|

Name |

KUID/KUID2 |

Author |

|

32ft_logset |

86661:9440302 |

Slugsmasher |

|

40ft_logset |

86661:9440303 |

Slugsmasher |

|

16ft_logset |

86661:9440304 |

Slugsmasher |

|

Logs |

-3:10001 |

Auran |

The cars to be used

|

Gauge |

Product

used compatible with the industry Decker log loader |

Name |

KUID/KUID2 |

Author |

|

NG 36 |

32ft_logset |

36ga |

86661:15039 |

Slugsmasher |

|

Standard |

40ft_logset |

SG Skeleton 42ft TRS |

86661:15047:1 |

Slugsmasher |

|

NG 36 |

32ft_logset |

36ga Skeleton 22ft Mich-Cal |

86661:15430:2 |

Slugsmasher |

|

NG 3 |

All sizes of M-Logs and Auran

Logs |

36ga Skeleton 42ft PCF |

86661:15049:1 |

Slugsmasher |

|

NG 3 |

32ft_logset |

36ga Skeleton 36ft D&C |

86661:15048:1 |

Slugsmasher |

HOW TO USE THE LOCO VERSION

The loco version has no interior.

Use the pantograph button to raise up and down the inclines tracks.

Use the reach bar to connect cars and to use the Decker log loader as a

locomotive for pulling or shoving a log cars train. The standard reach bar is

usually used with the NG cars listed above and the automatic with the standard

gauge cars.